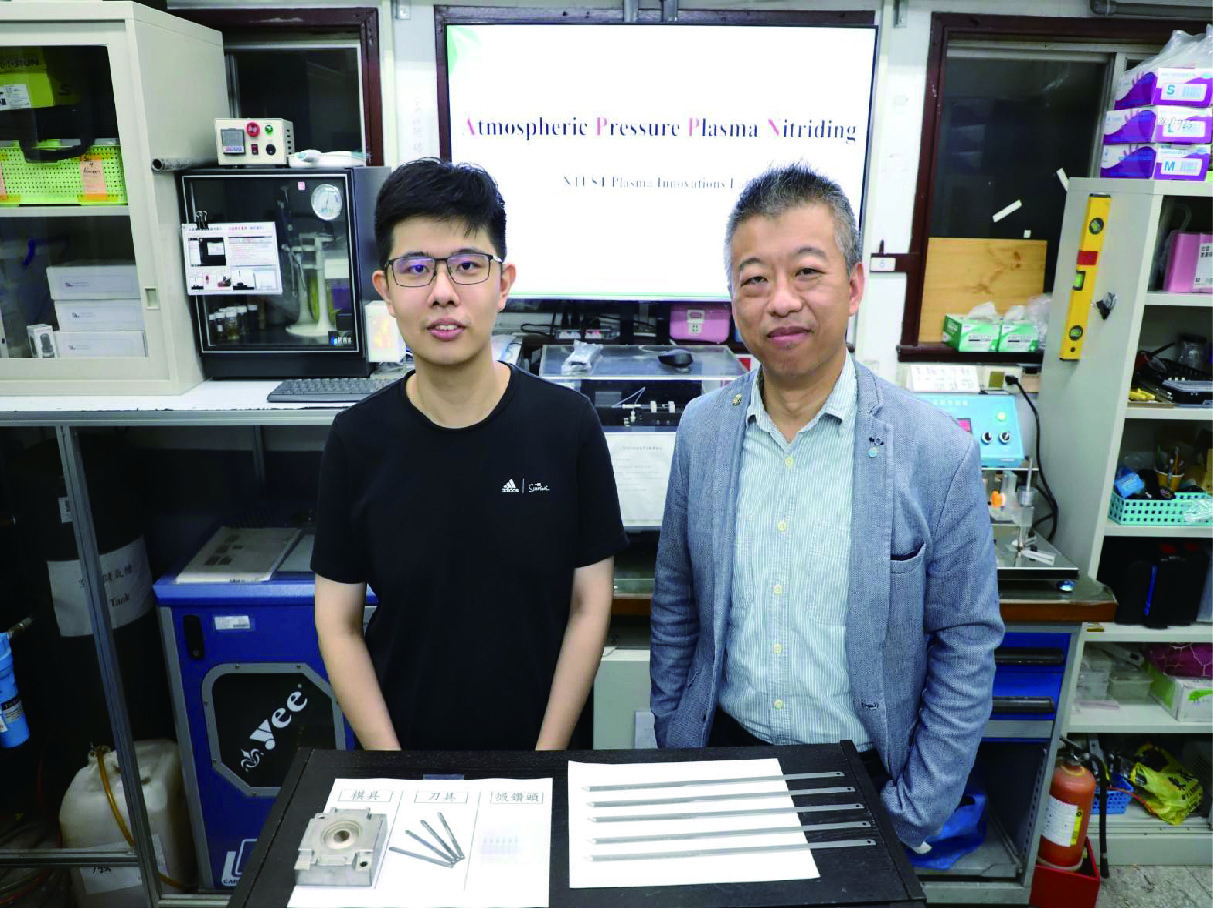

Professor Yu-Lin Kuo,Department of Mechanical Engineering

What inspired you to focus your research on atmospheric pressure plasma technology?

As a mechanical engineer, I have always been interested in exploring new technologies that can be applied to various industries. The unique properties of atmospheric pressure plasma technology caught my attention, such as its low temperature and fast speed. I was particularly interested in how it could be used in surface modification treatments and saw a lot of potential for its application in a range of fields.

What are some of the major benefits of using atmospheric pressure plasma technology in the manufacturing industry?

One of the major benefits of using atmospheric pressure plasma technology is its ability to improve the durability and lifespan of molds and dies used in the manufacturing industry. Additionally, the technology offers a green alternative to traditional surface treatment processes, as it can reduce carbon emissions during the process. It also offers a time-saving option for surface treatment, which can ultimately increase productivity and reduce costs. One of the benefits of this technology is for sterilization of surfaces. How has your team utilized atmospheric pressure plasma technology to address the challenges posed by the COVID-19 pandemic? During the COVID-19 pandemic, our team developed a disposable mask cleaning machine that uses low-temperature atmospheric pressure plasma technology to sterilize and eliminate odors from masks. This has allowed for the extended use of masks, which has been particularly important during the pandemic. We combined the plasma technology with robotic arms and automated equipment to create a highly efficient and effective solution for mask cleaning. One of the central processes of your work is nitriding.

Can you explain the key differences between traditional nitriding processes and the atmospheric pressure plasma technology you have developed?

The main difference between traditional nitriding processes and our atmospheric pressure plasma technology is that our process can be carried out under standard atmospheric pressure, without the need for a closed furnace. This eliminates the need for a vacuum environment, which can be expensive and time-consuming. Additionally, our technology provides a quick, eco-friendly process that improves wear resistance and hardness without compromising the lifespan of molds and dies. What are your future research goals for atmospheric pressure plasma technology? In the future, we hope to continue to explore new applications of atmospheric pressure plasma technology in various industries, such as agriculture and biotechnology. We also hope to further develop our plasma technology to improve its efficiency and effectiveness in surface modification treatments. Ultimately, our goal is to provide sustainable and environmentally friendly options for the manufacturing industry.