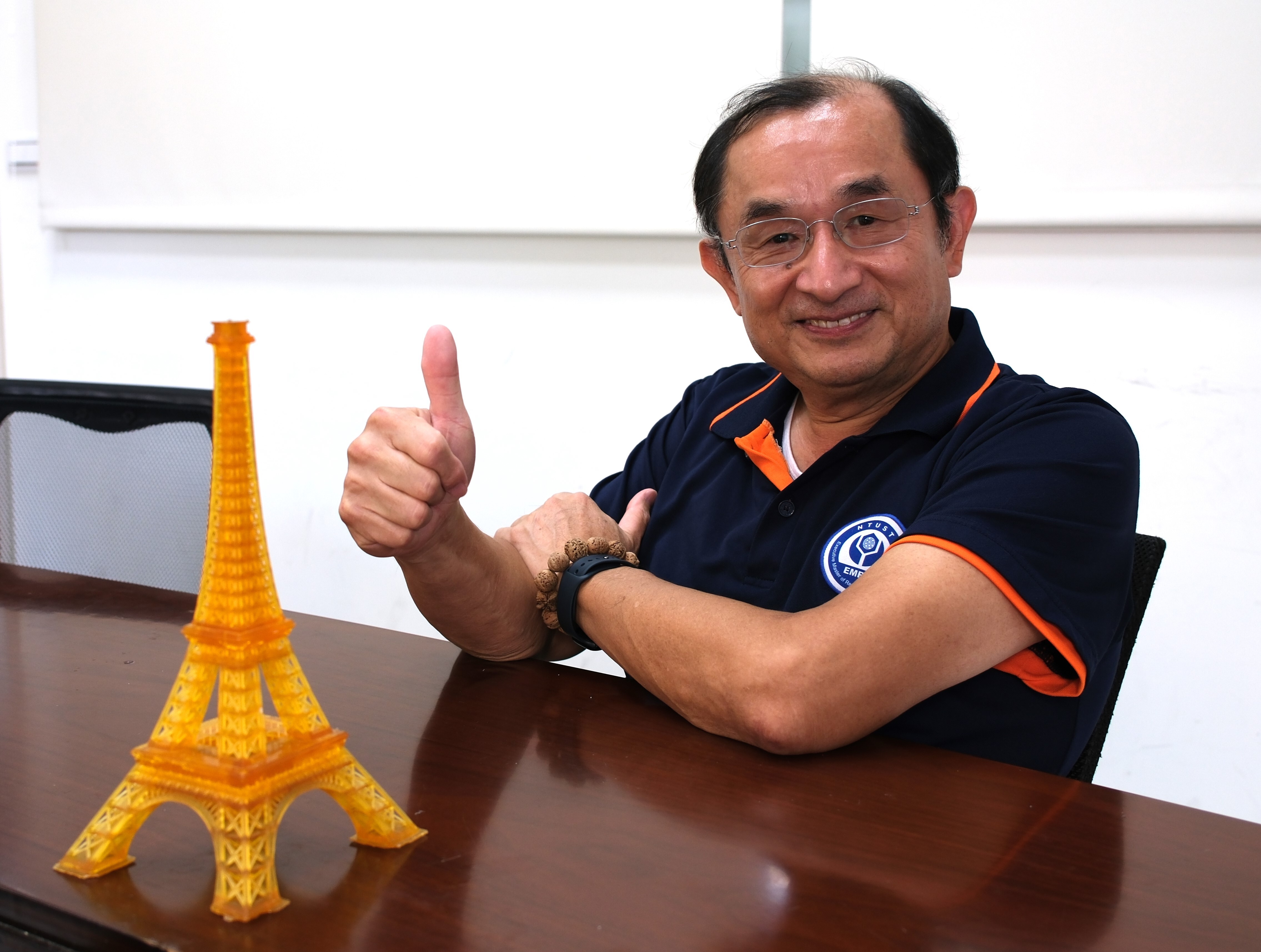

Precision at Pace: Jeng-Ywan Jeng's Pioneering Research in High-Speed 3D Printing

Jeng-Ywan JENG is a Distinguished Professor at the Department of Mechanical Engineering and the Director of the Taiwan High-Speed 3D Printing Research Centre. With a remarkable career spanning academic research, administration, and the private sector, he has been a driving force in 3D Printing research and education since the early 1990s, with over 40 papers and patents to his name. He is also the founder of Taiwan 3D Tech LLC, dedicated to advancing Smartphone 3D Printing.

Jeng-Ywan JENG is a Distinguished Professor at the Department of Mechanical Engineering and the Director of the Taiwan High-Speed 3D Printing Research Centre. With a remarkable career spanning academic research, administration, and the private sector, he has been a driving force in 3D Printing research and education since the early 1990s, with over 40 papers and patents to his name. He is also the founder of Taiwan 3D Tech LLC, dedicated to advancing Smartphone 3D Printing.

At Taiwan Tech, he held various administrative roles, including Dean of the College of Engineering and Dean of the Office of Research and Development.

His educational background includes a bachelor's degree in mechanical engineering from National Cheng Kung University (1985), an MSc in Advanced Manufacturing Technology from The University of Manchester (1990), and a PhD in Laser Material Processing from the University of Liverpool in 1992. He has also served as a visiting scholar at UC Santa Barbara (2002) and The University of Cambridge (2008).

Q: You became involved with additive manufacturing in the early 1990s. What sparked your interest in this field initially, and what has kept your passion alive for it until today?

My university education paved the way for my career in additive manufacturing. I worked a lot on automation processing and 3D modeling during my undergraduate years, and received a PhD in Laser Material Processing. That laid a strong foundation for the field of additive manufacturing, with its interdisciplinary nature, encompassing mechanical engineering, materials science, and opto-electronics. The field was just emerging in the 1990s, and back then the potential of 3D printing was not yet fully evident. I happened to become one of the first researchers in Taiwan to explore this field. The interdisciplinarity of additive manufacturing keeps fascinating me and remains a driving force behind my interest.

|

Q: Where do you see the most promising applications of additive manufacturing in the future?

When we chart the development of additive manufacturing, we can discern three distinct phases: the era of Ready Prototyping in the 1990s, the evolution into 3D printing, and, more recently, the emergence of Additive Manufacturing or Direct Digital Manufacturing (DDM), particularly since 2020. In this current phase, the emphasis lies on developing high-speed printing technologies to accelerate large-scale industrial production processes.

Additive manufacturing technologies hold the potential for a disruptive transformation in product design and manufacturing. In my view, DDM stands out as a "killer application" in orthodontics, and it could revolutionize mobility technologies in the automotive and aeronautic industries, offering the ability to create lighter yet stronger parts with improved mechanical properties. As DDM processes conserve materials, they also enhance the cost-effectiveness.

Q: Artificial Intelligence is currently revolutionizing various research areas. How is AI currently influencing your field, and what role do you anticipate it playing in the future?

AI already plays a significant role in our research field, and its influence is poised to grow further in the future. Presently, we have not fully integrated AI into our work, as our research primarily revolves around establishing design rules for DDM, a highly complex process. AI will eventually handle calculations and monitor processes, but we must first resolve design-related challenges to gather the necessary data for AI training. AI is expected to become integral in the subsequent phases of our research endeavors.

|

Q: Let's turn our attention to the 3D printing center at Taiwan Tech. What sets our center apart from similar institutions in Taiwan and internationally?

We are the first high-speed 3D printing center in Taiwan and even worldwide. As the pioneer researcher in Taiwan in this domain, I initiated the center's establishment and forged industry collaborations. Over time, our alumni have assumed pivotal roles in both industry and academia, both in Taiwan and abroad.

My recent appointment to the editorial board of the Journal Additive Manufacturing which provides academia and the world's leading industries with top-tier research papers and reviews, underscores our influence. I frequently invited to deliver talks at international universities to report about our research on high-speed 3 D printing. Undoubtedly, we are among the foremost institutions worldwide in the realm of DDM.

Q: You have mentored a substantial number of Master's and PhD students, including an increasing number of international students. What career paths do they typically pursue after graduation?

In the past, most of my students were Taiwanese, and they typically secured positions within the country's electronics parts industry. However, since 2015, in tandem with the semiconductor industry's explosive growth, a significant portion of our graduates has been recruited by semiconductor firms like TSMC. Photo-lithography is a key technology in the semiconductor sector, and our focus on stereo lithography aligns well with this. Our graduates are well-equipped with optical and laser technology expertise which is much needed in the semicondutor industry.

In recent years, our student demographics have become increasingly international, with a predominant influx from India and Pakistan. Many initially embark on their careers in Taiwan, but eventually receive attractive academic opportunities in their home countries. We tap into our alumni’s expertise and networks for recruiting new talents and building up research cooperation.

Presently, we are finalizing a collaborative venture with the Indian Institute of Technology Guwahati in Assam, which entails establishing a Joint Research Center and launching a Dual Degree Masters and PhD program. We anticipate that it will yield mutual benefits for both institutions.

Q: The Taiwan 3D Printing and Additive Manufacturing Show. Is held every hear in the Nangang Exhibition Centre in Taipei. Could you briefly elucidate the significance of this event?

Q: The Taiwan 3D Printing and Additive Manufacturing Show. Is held every hear in the Nangang Exhibition Centre in Taipei. Could you briefly elucidate the significance of this event?

I established the Taiwan Additive Manufacturing Association (TAMA) and initiated the Taiwan 3D Printing and Additive Manufacturing Show while I was TAMA president. This annual event boasts over 100 booths and turned into an important platform that brings together researchers, industry experts, and buyers. It attracts numerous visitors to Taiwan, many of whom also participate in educational summer short courses at Taiwan Tech.

I take pride in having established this platform for exchange, which continues to thrive and significantly contributes to the advancement of our field.