Taiwan Tech wins Five Future Tech Awards for breakthroughs in AI, Net-Zero, and Human-Centered Innovation.[13 Oct. 2025]

Jointly organized by the National Science and Technology Council (NSTC), Academia Sinica, the Ministry of Education (MOE), and the Ministry of Health and Welfare (MOHW), the 2025 Future Tech Awards attracted over 500 technology submissions this year. Ultimately, 83 key technologies stood out, with five teams from Taiwan Tech receiving awards. Their winning projects span three major fields - Artificial Intelligence, Net-Zero Technology, and Human-Centered Technology - showcasing Taiwan Tech’s diverse research and development strengths. The awarded technologies will be exhibited at the Taipei World Trade Center Hall 1 starting October 16, offering visitors an immersive experience of their real-world value and application potential.

Five teams from Taiwan Tech won the 2025 Future Tech Awards, covering three major fields -Artificial Intelligence, Net-Zero Technology, and Human-Centered Technology - demonstrating Taiwan Tech’s multifaceted research and development capabilities.

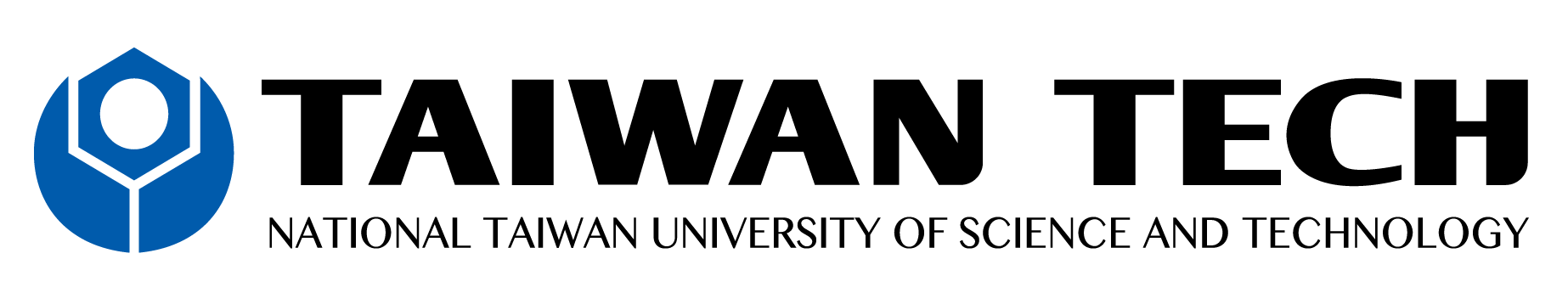

In the field of Artificial Intelligence, a research team led by Professor Pei-Jun Lee from the Department of Electronic and Computer Engineering has developed a high area-efficiency, low-voltage-operable sparse neural network accelerator. By integrating a high-performance chip with a self-developed edge computing system, the innovation significantly improves the energy efficiency of low Earth orbit (LEO) satellites and unmanned aerial vehicles (UAVs). Operating at low voltage, the chip enhances energy efficiency by 43.2% compared to existing architectures and extends operating time by approximately 10%, demonstrating high application potential in power-constrained space environments.

The team also developed an edge intelligent computing platform that utilizes a two-stage model compression technique to perform cloud removal, farmland segmentation, and disaster monitoring directly at the data source. This greatly reduces bandwidth and storage requirements, with applications spanning smart agriculture, national defense monitoring, environmental detection, and disaster early warning. In the future, the technology can be packaged as an AI module to accelerate its adoption in drone and satellite industries. Professor Li emphasized, “This is not just a chip—it’s a complete edge intelligence computing platform that will transform how humanity leverages space technology.”

A research team led by Professor Pei-Jun Lee from the Department of Electronic and Computer Engineering at Taiwan Tech has developed a high area-efficiency, low-voltage-operable sparse neural network accelerator. By combining a high-performance chip with a self-developed edge computing system, the innovation enhances the energy efficiency of low Earth orbit (LEO) satellites and unmanned aerial vehicles (UAVs).

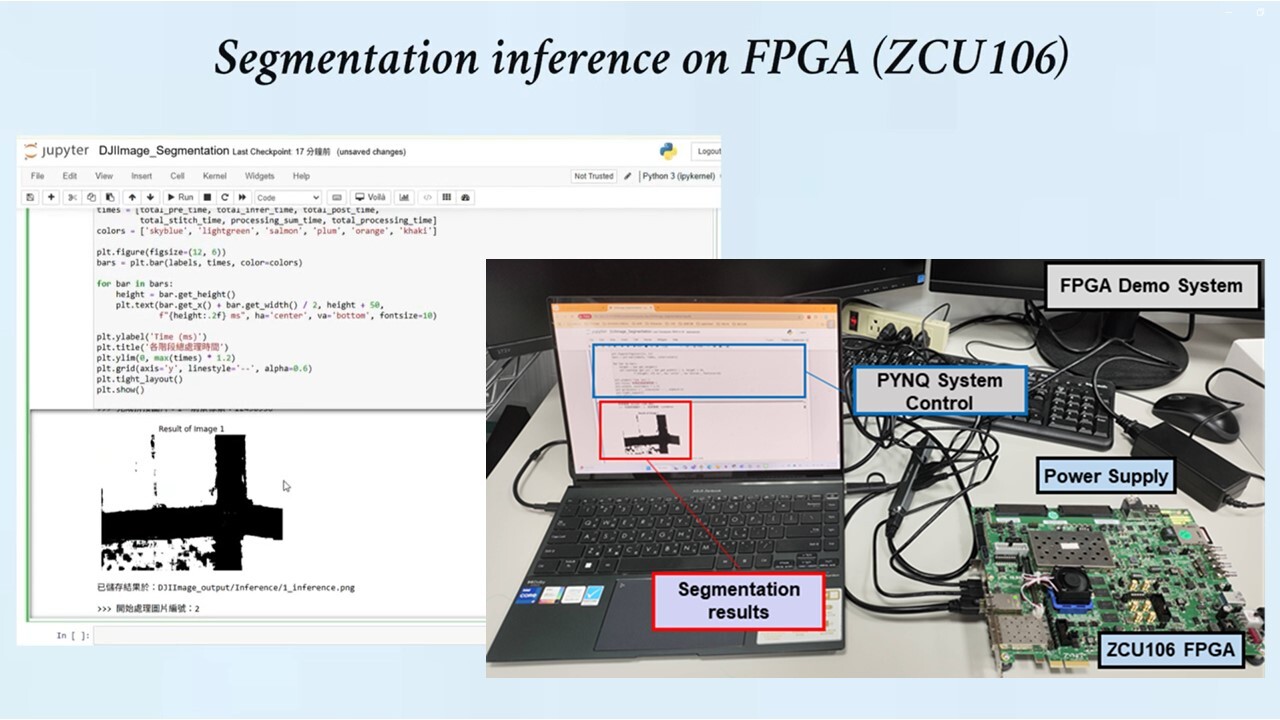

Amid the global push toward net-zero carbon emissions, many innovative technologies have emerged. A team led by Professor Chen-Hao Wang from the Department of Materials Science and Engineering has addressed the high energy consumption and severe carbon emission issues found in conventional methane separation for hydrogen production and high-temperature electrolysis. The team developed an electrochemical methane separation technology that operates under ambient pressure and low energy consumption, marking a breakthrough in the field of net-zero technologies.

Their innovation, titled “Non-Precious Metal Catalysts for Natural Gas Electrolysis, Oxidation, and Fuel Cell Applications,” centers on a membrane electrode assembly (MEA) composed entirely of non-precious metal catalysts. Using only low voltage, the system separates gases produced from methane cracking to generate high-purity hydrogen and solid carbon. The process requires no high-temperature or plasma energy input, resulting in near-zero carbon emissions. With its low energy consumption, low cost, and modular design, this technology is ideal for on-site hydrogen production in the petrochemical industry or green hydrogen generation at renewable energy sites for immediate use. Professor Wang noted that the technology can also be integrated with fuel cells for energy storage and power systems in urban homes and commercial buildings. Its low operating temperature, simple design, and high safety make it especially suitable for distributed energy systems and hydrogen-based microgrids.

A research team led by Professor Chen-Hao Wang from the Department of Materials Science and Engineering at Taiwan Tech has developed a non-precious metal catalyst-based natural gas electrolyzer that decomposes methane to produce high-purity hydrogen and solid carbon. The hydrogen generated through electrolysis can be supplied to a fuel cell to generate 0.87 volts of electricity, which can then power a rotating fan.

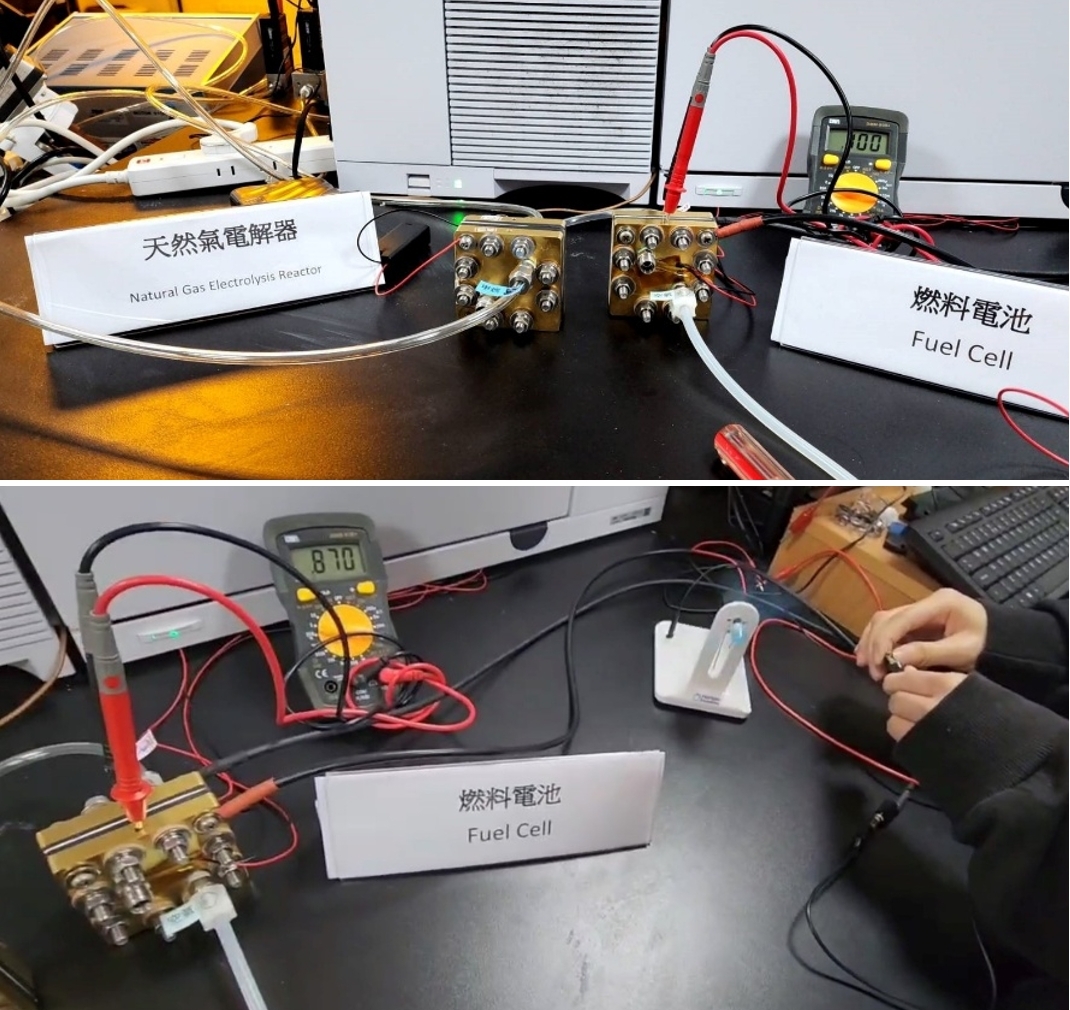

A research team led by Distinguished Professor Tai-Shung Chung from the Gradaute Institute of Applied Science and Technology has developed a three-layer composite hollow fiber membrane with a Pebax/m-PDMS/PES structure. Operating at room temperature and a pressure of 2 bar, the membrane achieves a carbon dioxide permeability of 1,253 GPU, surpassing the performance limits of existing Pebax hollow fiber membranes and improving efficiency by 100 to 200 percent, demonstrating exceptional CO₂ capture capability.

By optimizing spinning conditions and controlling membrane structure, the team utilized the immiscibility of wetting and coating liquids to enable a continuous fabrication process. They further enhanced interfacial compatibility between layers using plasma technology and incorporated newly developed selective layer materials (Pebax/SCA6 and Matrimid/PDMS-NH₂). This innovation successfully balances permeability and selectivity. The new hollow fiber membrane offers high flux, excellent selectivity, and long-term stability, reducing both system size and cost. Additionally, its modular design allows easy integration into high-emission environments such as coal-fired power plants and heavy industries, providing strong support for Taiwan’s carbon capture technology advancement and sustainable industrial transformation.

A research team led by Distinguished Professor Tai-Shung Chung from the Graduate Institute of Applied Science and Technology has developed a Pebax/m-PDMS/PES three-layer composite hollow fiber membrane that demonstrates outstanding carbon dioxide capture performance. The membrane can also be modularly integrated into high-emission environments such as coal-fired power plants and heavy industries, providing strong support for the advancement of Taiwan’s carbon capture technologies and the sustainable transformation of its industries.

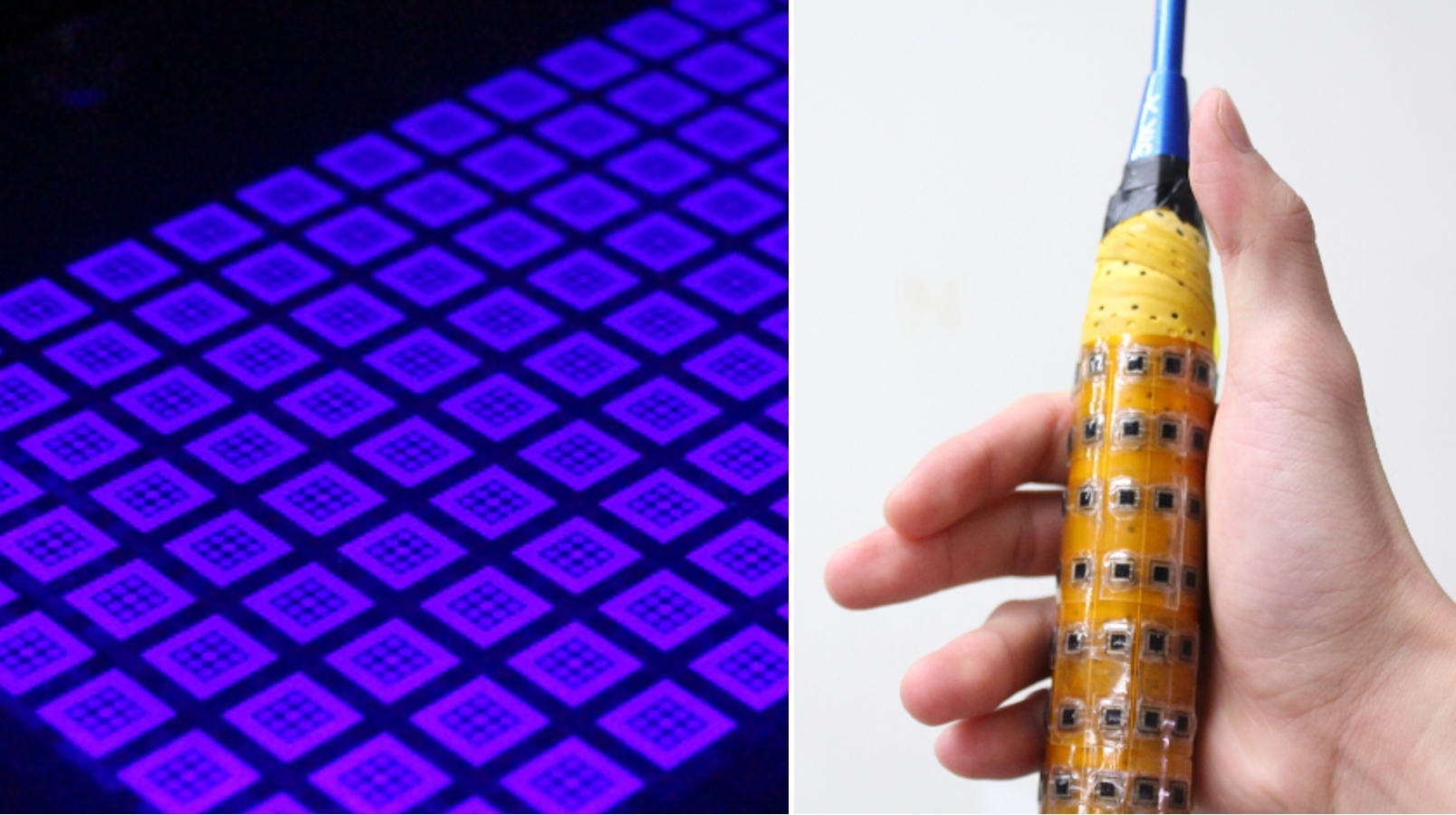

In the field of human-centered technology, a research team led by Distinguished Professor Pin-Chuan Chen from the Department of Mechanical Engineering has overcome the limitations of conventional sensing devices by developing a “multiscale 3D-printed flexible tactile sensor” using a fully 3D printing process. The sensor can be applied to wearable devices with complex curved surfaces and provides real-time feedback on motion and pressure, making it suitable for applications in sports training, health monitoring, and rehabilitation assistance.

Professor Chen’s team constructed flexible structures using soft materials to reduce the manufacturing complexity of sensors while allowing for customization based on specific needs. In the future, this technology can also be expanded to applications such as soft robotics and sensory feedback systems for smart prosthetics, opening up new possibilities in human–machine interaction and smart healthcare.

A research team led by Distinguished Professor Pin-Chuan Chen from the Department of Mechanical Engineering has used 3D printing technology to create flexible sensors that can be integrated into badminton racket grips. These sensors provide real-time measurements of human motion and applied force, helping to improve training efficiency and prevent sports injuries.

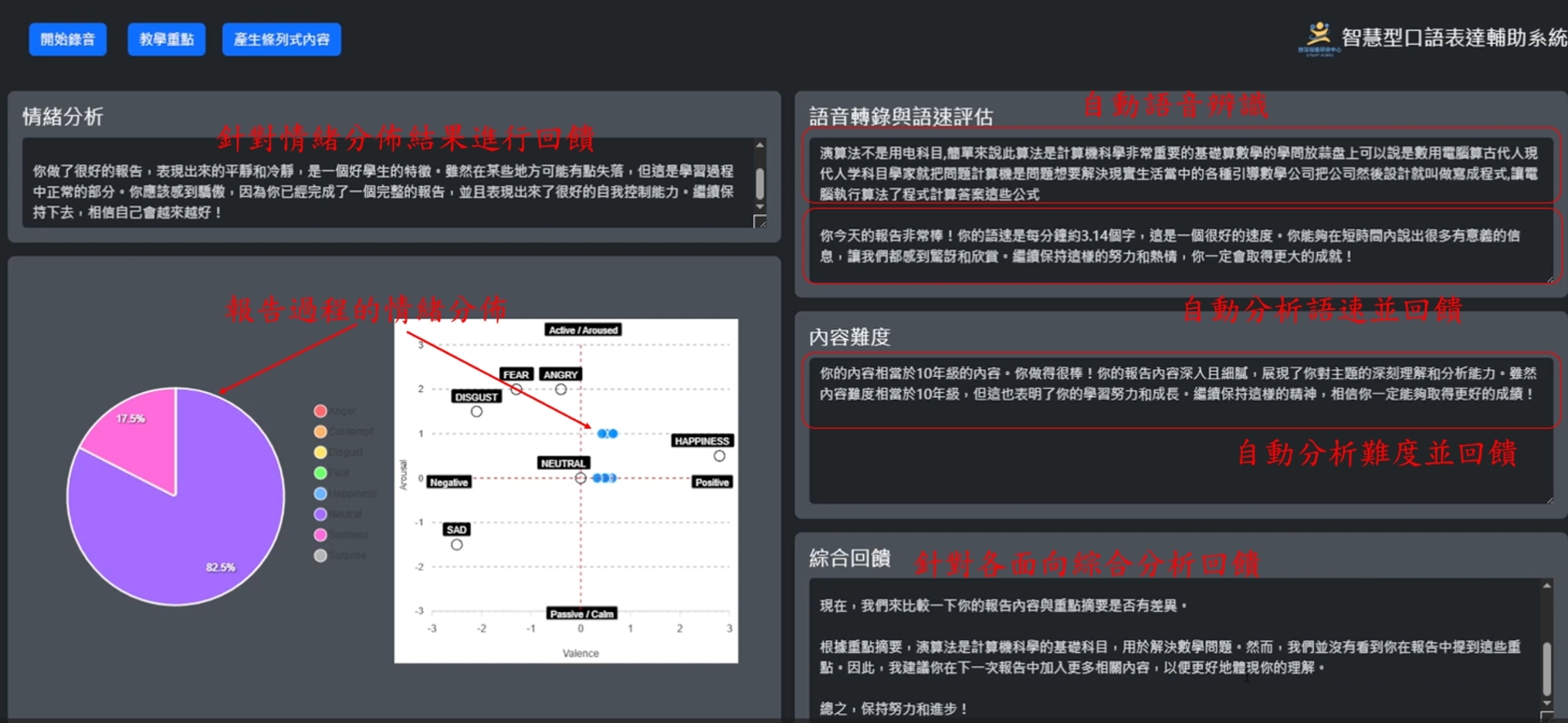

In addition, Distinguished Professor Su-Fen Chen and Assistant Professor Hou-Chiang Tseng from the Graduate Institute of Digital Learning and Education, together with Associate Professor Kuan-Yu Chen from the Department of Computer Science and Information Engineering, have developed an “Intelligent Oral Expression Assistance System.” The system integrates multiple artificial intelligence models to evaluate students’ oral presentations by analyzing content difficulty, omissions, speech rate, and emotional expression, providing real-time, personalized feedback to help students reflect and adjust. With the support of this system, students can also engage in self-directed practice outside of class, enhancing their oral communication skills.

Distinguished Professor Su-Fen Chen and Assistant Professor Hou-Chiang Tseng from the Graduate Institute of Digital Learning and Education, together with Associate Professor Kuan-Yu Chen from the Department of Computer Science and Information Engineering, have developed an “Intelligent Oral Expression Assistance System”. The system automatically provides personalized feedback on students’ oral presentations, evaluating content difficulty, omissions, speech rate, and emotional expression, helping students reflect and make adjustments.

From high-performance chips to low-carbon energy technologies, and from carbon capture to smart healthcare and educational applications, Taiwan Tech’s award-winning technologies at the Future Tech Awards closely align with societal needs, demonstrating both innovation and practical value. As these technologies continue to mature, they are expected to further drive industrial transformation and technological innovation, creating more opportunities for Taiwan to collaborate and compete in the global tech landscape.